| Camber

Compensator Spit

(Mk1, Mk2 and Mk3)

GT6 Mk1, Vitesse and Herald

This Unit is reported to also fit the Bond Equippe models that were

built using the Herald Chassis. |

GOOD NEWS

There is a US based company who has agreed to

manufacture camber compensators using the Curry Enterprises design

specifications.

Details can be found on their web site:

https://apex2apexmotorsports.com/

|

|

| On the early Spitfires

the road spring was attached firmly to the differential using 6 studs and nuts.

During hard cornering, body roll would cause the inside rear wheel to be pulled up

and lose adhesion to with the road surface. When this happened the swing axle would

have a tendency to tuck under resulting in what is called "wheel tuck".

This would produce a severe positive camber position of the inside wheel so if the

direction is changed rapidly (as in slalom or right-left turn combinations) you have

immediate and gross oversteer. Triumph modified the rear suspension with the

introduction of the MkIV model using a different way of attaching the road spring.

Instead of a fixed mount, there was now a metal box with a pivot pin that allowed the

spring to rock when the body rolled in turns.

This decreased roll stiffness and allowed the inside of the car to stay on the

surface and not tuck under.To compensate for the reduction in roll stiffness, the diameter

of the front anti sway bar was increased. |

|

| Above

is a photo of the center bracket mounted to the differential. Note the photo shows

the differential upside down for clarity. The

Bracket is attached to the lower part of the differential using the bottom three bolts

without modification. |

| A simple explanation of what

happens when you corner with the stock spring: The light

loaded wheel (inside of the corner) has reduced weight and this allows the spring to push

the wheel down into a positive camber position. After you go through that corner and the

body rolls back to the level position, the wheel that was affected stays in a gross

positive camber position. Therefore, if that wheel then becomes the loaded wheel in

the next turn, you will have excessive oversteer resulting in the tendency for the

rear of the car come around. The camber compensator greatly reduces this

"wheel-tuck" tendency. It is a rather simple operation, but very

effective. In fact it is more effective than the swing spring modification on the

later Spitfires, because it accomplishes the task without having to reduce roll

stiffness. An additional benefit is: At $225 (US) it is less expensive to add a

camber compensator than to upgrade to a swing spring. |

The competition department headed by R. W. (Kas) Kastner

recognized very early in Spitfire production the importance of eliminating the wheel tuck

problem in competition. So a camber compensator was designed to counteract this

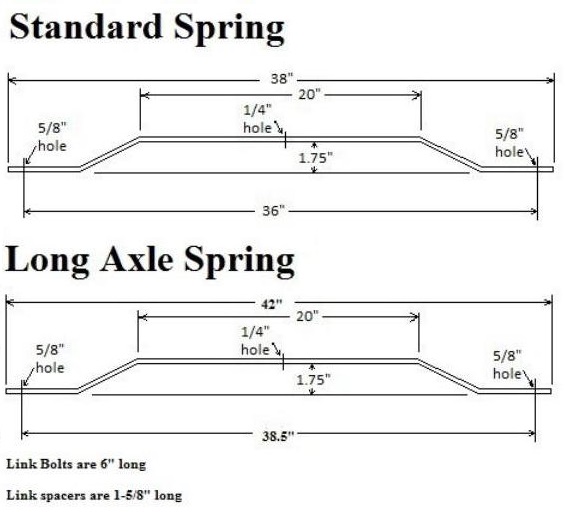

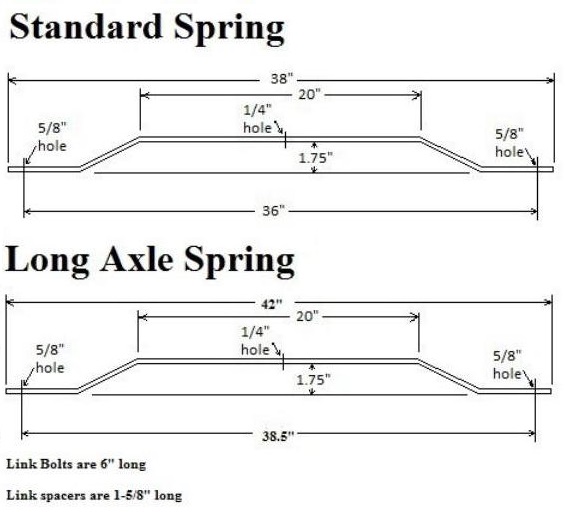

problem. The accessory (competition part number V 170) consists of three mounting

brackets a leaf spring and attaching hardware. The center bracket is mounted to the

bottom 3 differential bolts. The easily installed kit is, according to Kas Kastner,

"One of the best suspension modifications you can have on a

Triumph Spitfire". |

|

|

|

Above

is a photo of the right hand rear vertical link with Radius arm and Camber compensator

attached. |

Above

is an illustration of how the camber compensator appears when installed on a Spitfire. |